Electrical systems are super important for all factories and work areas. A good electrical setup, from powering machines to keeping things automated, makes sure things run well and safely. But unlike homes or stores, factories need more exact, careful planning and knowledge for their electrical setups. That’s why picking skilled Electrical Installation Services is very important for making sure things last a long time.

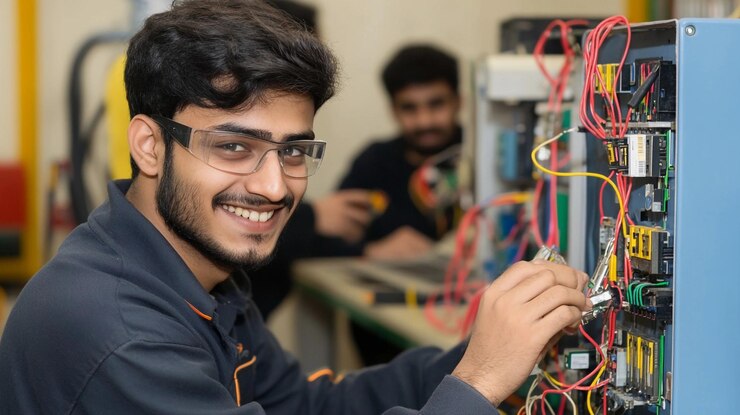

This is where SKPP excels — providing top-notch, safe, and effective electrical solutions created specifically for working environments.

What Are Electrical Installation Services?

Electrical Installation Services involve designing, installing, inspecting, and maintaining electrical systems that support a factory’s smooth operation. These systems include the electricity source, control panels, transformers, switchgear, and automation components.

In factories, these systems are complex and must adhere to very strict rules to prevent breakdowns, hazards, and wasted energy. A good electrical setup makes work more efficient and the workplace safer.

Key Components of Industrial Electrical Installation

1. Power Distribution Systems

The power distribution system ensures a continuous and reliable flow of electricity throughout the factory. It has transformers, switchgear, circuit breakers, and panels that send out electricity to keep voltage steady and cut down on lost energy.

2. Control and Automation Panels

Factory automation requires precise electrical connections. Control panels handle everything from production lines to managing temperature, making sure things are accurate and efficient.

3. Lighting Systems

Good lighting makes things safer, easier to see, and helps people get more done. Factory lighting systems are made to stay on all the time, even when things get tough.

4. Earthing and Grounding

Earthing systems are very important for protecting workers and equipment. They safely move extra electricity away, preventing damage and electrical shocks.

5. Cable Management

Neatly arranged cables make things safer and easier to repair. Cable trays and pipes keep wires safe from dirt, heat, and other things in the area.

6. Energy Monitoring Systems

When factories monitor their energy usage, they can decrease waste and lower costs — which is essential for maintaining sustainability.

Why Industrial Plants Need Professional Electrical Installation Services

Experienced Electrical Installation Services ensure rules are followed, things are dependable, and everything is secure. Here’s why factories depend on expert companies:

1. Safety and Compliance

Factory electrical systems must follow very strict safety rules. Professional teams make sure things are set up right based on the rules, so there are fewer risks.

2. Energy Efficiency

A system planned by experts wastes very little energy, which saves money and makes equipment last longer.

3. Reduced Downtime

Unexpected problems can stop production. A correct setup prevents problems and keeps operations running smoothly.

4. Customized Solutions

Every factory has different needs. Expert companies provide custom solutions to meet specific needs for production and safety.

5. Ongoing Maintenance

Professional services often have regular checks, testing, and updates to keep everything working as well as possible.

SKPP has earned trust across factories by delivering expert installation services focused on safety, energy conservation, and durability.

The Process of Electrical Installation in Industrial Plants

When the installation process is well-organized, it makes sure all parts work together the way they should.

1. Site Inspection and Planning

Experts figure out how much power is needed, spot any problems that might come up, and get everything organized well.

2. System Design

Engineers create full power setups, wiring plans, and safety steps made just for what the plant needs.

3. Material Selection

Good, approved parts are picked out to make sure they last and follow all the safety rules.

4. Installation and Integration

The team puts in systems, from power boxes to machines that work by themselves, making sure they connect easily.

5. Testing and Commissioning

Careful checks show that each system works safely and does what it is supposed to do in a good way.

6. Documentation and Handover

Full reports and official papers are given to help with checks and to look back at later if needed.

Common Challenges in Industrial Electrical Installation

- High Voltage Requirements – Big machines need a power supply that is always strong and you can count on.

- Environmental Conditions – Hot, dusty, and wet weather can make the system not work as well as it should.

- Space Constraints – Limited space makes wiring and maintenance operations difficult to complete.

- Safety Hazards – If things are not set up right, work might stop or people could get hurt.

A helper who knows what they are doing like SKPP India helps companies fix these issues with careful ideas and skilled work.

Choosing the Right Electrical Installation Partner

When picking a company for Electrical Installation Services, think about:

- A history of doing well on factory projects

- Official papers and following the rules

- Helpful support and repair services

- Clear costs and project times

- Using new tools and ways of doing things

SKPP India is known for giving reliable and good electrical installation answers that meet factory rules and what businesses need.

Conclusion

Electrical installation ensures a factory is both safe and capable of operating efficiently. A system that is carefully planned and expertly installed ensures smooth operations, safety, and cost savings. Investing in professional Electrical Installation Services not only supports daily functions but also maintains high output for an extended period.

SKPP India provides comprehensive installation solutions that enable businesses to build robust electrical systems that comply with safety guidelines and are ready for future growth.

FAQs

1. What are Electrical Installation Services?

These include designing, setting up, and maintaining electrical systems, like power, lighting, and control panels in factories.

2. Why do industrial plants need professional electrical installation?

To be sure they meet safety rules, have fewer stops, and make everything run more smoothly overall.

3. How often should electrical systems be inspected?

Regular checks and maintenance every six months are recommended to keep everything running smoothly.

4. Can installation quality affect production?

Yes. If it’s set up badly, things might break often and waste power, but a good setup keeps things running without stopping.

5. Why choose SKPP for electrical installation?

Because SKPP gives special, safe, and reliable answers made for the needs of factory places.